There are a ton of different stucco sprayers out there nowadays, certainly more to choose from than there were 10 years ago and they have some pretty unique features that can make applying plaster much easier and faster, in some cases.

I try to find some of the best mortar/stucco sprayers that would appeal to most people, depending on their specific needs and what things they would be looking for in these types of sprayers.

If you get a chance be sure to scroll to the bottom of this post and you will find some helpful topics that helped me craft this page and will give you a better understanding of some of the different features and requirements that these need in order to operate effectively.

Sprayers For Stucco Basecoats, Mortar, Plaster, Etc.

First up, are some of the best sprayers out there for some of the thicker materials that one might spray on such as stucco base coats, mortars, cements, earthen plasters, etc.

The Highest Rated Mortar/Stucco Sprayer Out There:

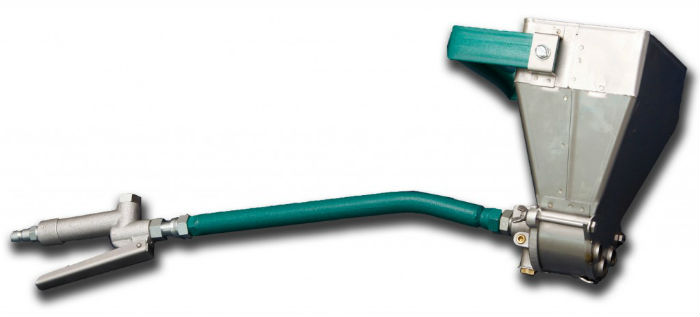

The first sprayer (Toolcrete 3 Jet Wall Sprayer) is the most popular sprayer and was chosen as Amazon's choice out of all of the stucco sprayers in the category.

This sprayer offers a good balance between price, quality and functionality and is why I think it should be at the top of the list.

This is the highest rated and most used sprayer out there but it is only suited for walls and not ceilings, so keep that in mind.

This particular model comes with three different jets you can use simultaneously or you could simply use a single jet or two jets, depending on the material you're applying and the force that it is applied.

The CFM requirements for this mortar sprayer are 7cfm@90psi for the smaller jets and 12cfm@90psi for the larger ones. The

A More Affordable Stucco Sprayer...

This Benron Plaster Sprayer is one of the most affordable models out there and it has a lot of comparable features to other models that cost $100 more.

This has four different jets, which is pretty impressive especially for a more affordable model and a smaller more stout hopper then Toolcrete's hoppers.

Another added bonus to this sprayer is the fact that Benron offers a two-year warranty on all of their sprayers instead of a one-year warranty, like Toolcrete's.

This sprayer is perfect for beginners or somebody he doesn't want to spend a whole lot of money on one of these and would like to try them out before upgrading.

A Sprayer Made For Walls & Ceilings:

This Toolcrete Sprayer is made to shoot both walls and ceilings, without making a huge mess, like a lot of the other models would. It is specifically designed to handle ceilings, due to the angle of the jets and the position and shape of the holding tank.

This is one of the only models out there that can spray both walls and ceilings, without making a huge mess and spilling out of the hopper.

As with all Toolcrete sprayers, this comes with a one-year warranty but their products are built so well that the company even states that very few people actually use the warranty, nice peace of mind when buying any product.

Another Benron Sprayer Makes The List:

This is another Benron Stucco/Mortar Sprayer and is a little different than some of the other models.

The handle has a little bit different shape to it and is a lot more comfortable to use because of its shape. It fits a lot more naturally into the users and and reduces fatigue at the same time.

Since this is another Benron sprayer, it comes with a two-year warranty which is the best in the business at this point in time.

All of their sprayers are also made from stainless steels and they don't rust over time like the cheaper sprayers out there would.

Sprayers Made For Finish Coats:

These sprayers are made for thinner applications of materials like stucco finishes, waterproofing coats, slurries and so on. These have a much more consistent spray pattern that is very uniform, if applied correctly. Here are some of the top models I found...

The Marshalltown SS20 Sharp Shooter 2.0:

The Marshalltown Sprayer is one of the best options out there and one of the most affordable ones.

It has a dial on the front where you can adjust the spray pattern and has many advantages over Marshalltown's SharpShooter I, according to the manufacturer.

This is designed to spray a wide range of materials but will work awesome with stucco finish coats and could also be useful with drywall mud so if you have both projects going on this would definitely be a sprayer that would fill a gap and provide a lot of value to you.

The hopper can hold a maximum of 2 gallons of material and you can also spray ceilings with it as long as you don't fill the hopper up all the way.

For the price and the amount of features you get with this sprayer it is definitely one of the top models as far as finish sprayers go.

The Ez-Tex SprayAll By Benron

The Benron EZ-Tex SprayAll is a very versatile finish sprayer on steroids! It has a very nice spray pattern and can actually spray finish materials with up to 1 inch long fiberglass pieces in the material.

The manufacturer states that can spray more viscous finish materials which is a unique feature that many of the other competitors sprayers can not accomplish.

The handle is another nice feature and uses the natural ergonomics of our hands to reduce user fatigue, which comes in very handy is specially for those larger jobs that require several hours of spraying at a time.

This sprayer does come with a pretty hefty price tag, more than $300 at the time of this article but is well worth it if you have a large project or are unfamiliar with plastering tools and are looking to finish the stucco on your house yourself.

The Texture-Pro 200 From Wal-Board Tools:

The Texture-Pro 200 by Wal-Board Tools is another choice that is the least expensive model on the list but is more geared towards drywall mud but will work for finish coats too.

These aren't the best sprayers out there and from my experience they do tend to get clogged pretty easily but they will work for most applications and do a pretty good job if you keep the orifice clean and the mud at the right consistency.

One of the most convenient features about this particular finish sprayer is the fact that you can find them at just about any Home Depot, making it convenient.

Just be sure your local Home Depot stocks it because I know that not every store will have them in stock, from personal experience.

A Few Things To Consider:

Compressors & Hoses (Requirements) Needed For These Sprayers:

Compressors: A lot of these sprayers will require at least 7cfm @ 90psi of air flow when using the smaller nozzle sizes and if you plan on using the larger nozzles you'll need one that can pump out a massive 12cfm @ 90psi. These are very expensive compressors, in case you're not familiar with these units of measurements.

You can always rent one of these compressors by a lot of people who have used these sprayers find that a lot of rental yards do not have compressors that have these capacities.

If you plan on using knees often you will really want to consider purchasing an electric (220v) compressor with at least 5 hp or a 6.5 hp gas powered compressor (MINIMUM).

Tanks: The more air your compressor has the better these will work, so you can also add an extra air tank (15 - 30 gal. recommended) for increased pressure and efficiency.

Having extra tanks are only optional and not mandatory as long as you have a worthy air compressor.

Air Hoses: Most of these will run off of a standard 3/8 of an inch air hose but if you have a more powerful compressor then the minimum requirements then a half inch air hose is recommended.

Just make sure that your male and female adapters fit correctly to the sprayer's connector.

Let's Talk Pricing:

I noticed that most of these mortar and stucco sprayers were priced around $200-$300 on average for the more reputable models but I saw a price ranges from $70 all the way up to $350, which really came down to how many jets the unit had (power and volume) and the materials that the actual sprayer was made out of.

The Cheaper Models: There were a few different sprayers in the $70-$100 range, which I was very curious about but there were not nearly enough customer reviews to base anything off of how well they work and how long they last.

I did notice that most of these are not made with stainless steel but instead a zinc material which is not as good but would still probably work, so not a huge deal breaker as far as that goes.

I can't speak for how well the jets work or the overall functionality which I would be more curious about because they were significantly less than some of the other models listed.

The Mid-Priced Models: The sprayers and this price range which I would consider to be around $150-$250 in price were pretty decent. These used stainless steel containers where the mud is held and either brass and/or stainless steel nozzles which are two of the best materials you can use for these types of tools.

There were tons of customer reviews for many of these products and it made it really helpful to see how well they worked, what people were using them for and some of the challenges that people face when running these mortar sprayers.

Most of these were still only geared towards applying material on walls and not overhead, not under $250, at least.

The Higher-Priced Models: These sprayers tended to be the "top models" that were able to spray both ceilings and walls and had up to four different jets so they have the maximum amount of volume output as far as material on the wall per minute or per hour goes.

It really didn't make sense to me that the more expensive models were able to spray ceilings/soffits because it seemed like it was just a simple angle change on the sprayer itself and wouldn't justify an additional $50-$100 just for that small little detail, but that's just my opinion.

Spraying Base Coats VS Finish Coats:

There our two main types of sprayers out there and you should be aware that these are designed to spray different materials and typically one sprayer will usually spray a base coat material for a finish coat type of material. It is important to know the difference between these two sprayers and which one can spray what material.

Spraying Base Coats: Sprayers that are able to apply base coat materials are specially made to handle the thickness of the material because of the larger holes in the nozzles and the amount of force that is used to pump the material through those nozzles.

These are able to spray finish materials but you will get nowhere near a uniform and consistent finish, like you would with a finishing type of sprayer.

Spraying Finish Coats: A sprayer that is designed to spray finishes and topcoats will have much smaller holes in the nozzle and require a lot less pressure to pump that material out of the gun.

These have different spray patterns and depending on the quality of the sprayer you get these can actually spray on a very consistent pattern that can be left alone and finished off with a merely the sprayer itself.

These types of finishes are usually known as a dash type of finish.

Walls, Ceilings Or Both?

Most of these stucco and mortar sprayers are made for spraying material on walls but a couple of different models actually have the ability to spray ceilings as well, due to the angle of the jets on the sprayer itself.

This is really the only major difference between units that can spray a wall and units that can spray a wall or a ceiling, that and of course a price difference of about $50 - $100.

Let's Take A Look At Warranty Information...

I found that these sprayers typically have either a one-year or two-year warranty and these are offered by the two main companies that sell these sprayers: Benron and Toolcrete. The other sprayers did not have any warranty information that I could clearly see so it's hard to know if they have a warranty policy at all.

Be sure to use your mortar sprayer as soon as you get it or very soon after getting it to ensure that it works properly and if their are any problems you don't run into that limited time frame that the manufacturer offers for their warranty.

What Am I Going To Be Spraying?

These can spray a ton of different materials because of the large holes on the hopper, not just stucco and mortar.

These can actually spray light weight shotcrete material, earthen plaster mixes, other plaster materials and other types of materials that have the same type of consistency and makeup.

Features That Will Make A Difference...

Jets: These have many different jets configured on to the sprayer itself in these usually range from 2 to 4 different jets. These jets come with different nozzles (a larger and a smaller one) that can spray more material on the wall depending on which nozzle you use.

You also have the ability to block off 1, 2 or 3 nozzles using a cap, giving you a more precise spray pattern and less intensity at the same time for specific job requirements.

The jets are typically angled straight ahead of the hopper but some models have them angled upwards a little bit in order to spray a ceiling with out the material dumping out of the hopper.

Handles: The handles usually come with a short and long version depending on your sprain requirements and the amount of space you have to move around.

The longer handles are more comfortable and give you a little bit more control over the sprayer itself and the shorter handles are for tighter areas where your spray angle would be off if you had the longer handle attached.

Hopper: The hoppers are pretty standard but from what I've noticed Toolcrete's sprayers have a taller more narrow hopper and Benron's hopper design is shorter and a little stockier.

The capacity of the hoppers is usually about the same though, somewhere around 1 gallon of material when full.

Construction & Materials Used: Coming Soon!