With all the terminology surrounding stucco, it can be confusing trying to figure out what certain terms mean and stucco lath is one of those terms used in the stucco process that you might see referred to often, but what is it?

Let's explore lath in more detail and by the end of the article, you should have a firm grasp on what it is and what purpose it serves.

What Is Stucco Lath?

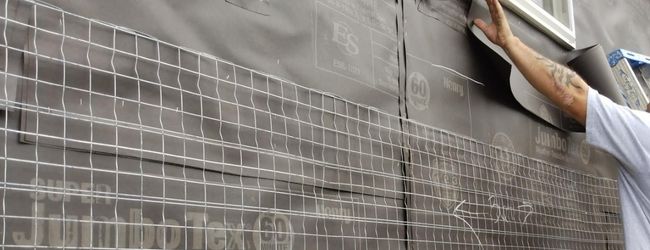

Lath is simply the first step in the stucco process and is responsible for water proofing the wall and provides a base that the base coat can adhere to.

It consists of two plies of water-resistant paper, sometimes EPS foam, wire and other metal components that make up the essential “framework” that needs to be in place before any material is applied to the walls. It attaches to the wall via the studs and is the foundation for three coat and one coat stucco systems.

The Waterproofing Element: Stucco Paper

Stucco paper is actually infused with an asphalt that is resistant to water and moisture and has similar characteristics to roofing felt. It is available in a couple of different thicknesses and can be found in a one or two-ply roll. It is usually attached to the wall with a stapler, using smaller staples, similar in size to the ones you would find in an office setting.

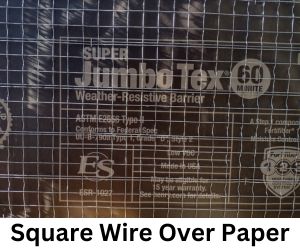

10 Min. Paper vs 60 Min. Paper: There are commonly two different paper weights that are used most of the time for today's stucco projects and these two choices are called 10 minute paper and 60 minute paper. The rating is based on minutes, which correlates directly to the weight of the paper itself.

60 minute paper is much thicker than 10 minute paper and can withstand moisture, for a longer period of time. There are other paper options out there, but these are the two most common and most widely available.

One-Ply vs Two-Ply Paper: If you were to buy stucco paper, you might see a choice between one ply or two-ply and it is exactly what it sounds like, you will get either one or two pieces of paper (on a large roll).

Two-ply paper is always recommended over single ply because it provides double the protection, right? Single ply paper is usually used for covering the ground before you start applying any base coats or finish coats and works well for that, but I wouldn't recommend using it as part of the lath process on your walls, opt for two-ply instead.

Stucco Wire: How The Material Sticks!

Stucco wire comes in various thicknesses, types and styles to match specific commercial, residential and personal specifications or situations. This can add to the confusion that some people have when looking at stucco wire. The wire comes on a large roll and is usually around 38 inches in height and more than 100 feet in length.

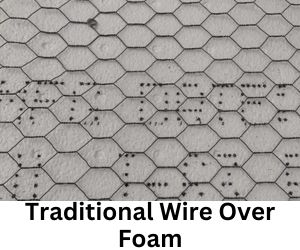

Stucco wire is thicker and stronger than say “chicken or poultry wire” and is furred, meaning it sticks out of the wall a little bit, to allow the cement to get behind it and hang onto the wire. This is referred to as “keying the material” into the wire.

Wire Styles: Even though stucco wire serves the same purpose and performs the same, it can come in different styles, which adds to the confusion of the already many different options that are out there.

Wire Gauge: There are two main wire gauges that are available when it comes to wire that is attached to the walls and this is either 17 gauge wire or 20 gauge wire.

- 17 gauge wire is thicker and used for three coat stucco applications. There are many styles available in this gauge, including options when it comes to the furring of the wire.

- 20 gauge wire is thinner and is only used for the one coat stucco system, making it easy to identify. There aren't a lot of options for this wire either, like there are for the 17 gauge wire, so it makes buying it a lot simpler.

Other Important Metal Components Used:

There are other pieces included within the lathing stages that are equally important as the paper and wire itself. These are made out of galvanized metal (in most applications) and are a crucial for certain areas or situations of a stucco wall.

* Many of these item come in different finishes (stainless steel, copper, etc.) that you might need in certain circumstances, like in coastal areas, but galvanized is the standard for most applications

There may also be different options when it comes to sizes or depths for certain items like weep screed and plaster stop that will suit specific stucco systems or situations.

Weep Screed:

Weep screed is found at the bottom of walls and has many holes in it to allow for water drainage. It comes in two main styles that are used today: a 90-degree angle ("J" shaped) and a 30-degree angle (referred to as number 7 weep screed).

They are used for both three coat and one coat stucco applications and come in different sizes and widths.

Sizes: For three coat stucco systems, you would typically use a weep screed that has a 7/8" ground depth and for one coat stucco systems, a 1 3/8" ground depth is used. Here is a good link that describes it in more detail: weep screed article

Plaster Stop:

Plaster (or J) stop is actually a "J" shaped metal flashing type of material, and is a termination point for stucco, which is sometimes used around doors and the top of walls for a cleaner look and to add a termination point for the stucco when it is needed.

It resembles a weep screed, but there are no holes punched into it, so it makes for a cleaner look in areas where you will see it. The image below shows a piece of plaster stop that is installed around a door and painted to match the door color and it blends in great.

Expansion/Control Joints:

An expansion/control joint is used to break up the stucco in order to lessen the chances of cracking. It can be very wide (3″ or more), or very narrow, with most modern types having a 5/15" gap. Expansion joints can move, while control joins are stationary and provide more of a controlled breaking point.

It is usually painted to match the color of the stucco and is generally needed where there is an area of stucco greater than 120 square feet or more on walls and 100 sq. feet on soffits. Other conditions apply where expansion or control joints may also be needed, but the square footage above is a good general rule.

* Walls without natural breaks (such as windows and doors) will have a far greater chance of developing cracks if not using expansion/control joints.

Corner Aid:

Corner aid is used on corners and edges that need to be defined and strengthened and comes in two different styles, bull nose (rounded) and straight.

The straight version (pictured below) forms a 90-degree angle that makes a sharper edge profile and the bull nose is designed for rounded, more subtle corners. They come in 8' and 10‘ lengths and are usually installed with staples or nails after the wire has been installed.

Arch Aid:

Arch aid acts the same way corner aid does, it simply bends to conform to arches and curves. It can be a bit tricky to install and does take some skill to master, but will make all the difference in the world around archways.

Don't Forget The Staples & Nails!

In order to fasten the metal lath to the substrate (plywood, masonry, etc.) you will need to either nail or staple the wire to the substrate itself. Typically, staples are used to do this, along with a staple gun and a compressor.

It is also possible to nail the wire off by hand for smaller areas, or to hang the wire, plaster stop, weep screed and/or corner aid. For larger areas, a stapler should be used as it will save a lot of time, but is not mandatory. All fasteners should be galvanized or at least rated for exterior use to prevent corrosion from taking place.

Nails are a great way to quickly hang wire and other lath components quickly and accurately. There are a few types used in stucco applications and becoming familiar with each type can be very helpful.

- Dog eared nails (or furred nails) are not really used anymore, because the wire itself is furred. These nails were used a few decades ago to help hold the wire off of the wall itself. They should only be used if you are doing a remodel that uses these types of nails and unfurred wire, otherwise don’t bother with them.

- Roofing nails are used sometimes because they are usually galvanized and have a large head on them, which holds the wire in place very well.

- Galvanized 4 penny nails are also use in three coat stucco systems and are bent over after being driven in halfway or more and holds the wire in place.

- Staples are used more often than not and are a quick way to attach the wire to the substrate. There are specifics on the size of the staple, including the length of the staple and the size of the crown, check with your local building department. You will also need a small compressor and staple gun to shoot these in.