If you need to mix up a little bit of stucco then having a drill that is designed for mixing materials like stucco, concrete, mortar, then set and so on can be so helpful and it will come in handy for so many things, especially for those of you out there that are avid DIYers.

A High Rated, Quality Mixing Drill:

The Bosch GBM9-16 is one of the highest rated mixing drills out there right now and is offered at a reasonable price, considering it is such a durable drill too.

Usually, the more durable drills have a much higher price tag than what this one is going for.

This drill would be the best bet for those of you out there that want something that will last many years, without breaking the bank.

An Affordable, High Quality Option!

This Ridgid drill is a great deal when you consider the price of the tool and the quality, two things that don't seem to go together nowadays.

I have personally used this drill for many years and it is still going strong, even to this day.

This is the drill I would recommend for those of you out there that want a decent price with top tier quality.

Another Reliable Mixing Drill Option...

The Makita DS4011 is another drill that made the list and is known as being one of the most reliable mixing drills on the market and if you're at all skeptical just take a look at the reviews.

Makita is one of the best tool manufacturers out there and you can bet that this power mixer is no exception.

This Makita is recommended for people who are looking for longevity first and foremost and want to know that it will do the job time and time again.

A DeWalt Option To Consider...

DeWalt had another corded option and it is similar to the Bosch and Makita options listed above, with similar specs.

The price is a little higher, but is still a fantastic choice that has a ton of reviews to back it up.

A Budget Friendly Option

I also wanted to include a "budget friendly" option in the lineup for those of you out there that didn't want to spend the money on some of the more robust options.

This Bauer option is only available at Harbor Freight, but is worth the time and energy to go and grab it if you want to save some money.

If you don't have a Harbor Freight near you, there are plenty of other lower cost options out there to choose from.

A High-end Mixer For Professionals...

The Collomix X01 is a brand that most people aren't familiar with but is one of the higher-end models out there and is in fact one of the lower end models of the company's whole product lineup.

This particular mixer is definitely at the higher end of the pricing spectrum when compared to the rest of the models we looked at but has many upgraded features that some of the other ones don't have either.

There is not a whole lot of feedback on this particular Collomix mixing drill on various retail sites but it does provide a ton of power, has some of the best ergonomics that you can find in a drill and has pretty cool features like quick disconnect for the paddle and electronic speed control, things that you just won't find in other power mixers.

A Dual Paddle Mixer That Is Pretty Cool...

The Collomix X055 is one of the top of the line dual auger power mixers out there, not the only one but definitely the best.

These are extremely expensive and can cost anywhere from $800 and up, depending on where you look.

These are extremely easy to use and reduces the amount of time it takes to mix up a batch of mud by at least half the amount of required time it would usually take.

One unique feature to the Xo55 power mixer is the fact that the two augers spin in opposite directions, which will not spin the bucket as you are mixing like a traditional mixing drill would.

The Different Shapes Of Drills:

As you may have noticed above, there are a couple of different drill configurations or shapes that they come available in and it doesn't really make too much of a difference as far as mixing capability is concerned, which one you go with but comfort is really where the design comes into play.

Some people prefer the traditional type of mixing drills that are basically shaped like a bigger drill, mainly because that's what they really are and people are more familiar with the design because they had used it for so many years.

I'm not sure about and it's just my personal opinion on the matter, the only reason (that makes sense) I can see why people may prefer these over the other types.

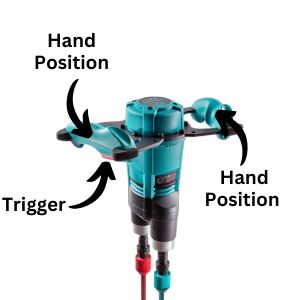

The other types of designs that these mixing drills can have almost reminds me of how you would grip a steering wheel in a car and seems to be much more comfortable, just because your wrists are positioned in a more natural manner.

If you do have wrist problems, I would recommend going with one of each drills instead of the other ones because you can control the drill a lot more and they don't torque your wrists in the same way that the other standard type of drill configurations do.

What Type Of Paddle/Mixer Attachment Is Best?

After you have your mixing drill you will need to get a paddle attachment for it in order to mix up your stucco, cement, grout, mortar or whatever else you happen to be mixing. When you look at some of the available paddles out there you can be easily overwhelmed at the amount of choices.

A lot of these will work pretty well but I am going to recommend two different paddles just to make things a little less confusing. These are the two that I use on a consistent basis, am familiar with and I know that they work.

Do I Have To Use One Of These Drills?

These drills are specifically made for mixing up different materials like drywall mud, stucco, mortar, concrete and so on and are geared specifically for this type of task.

Not all drills can do this and in fact you will more than likely burn up one of your drills if you try to mix up these materials with a standard drill that is not suited to handle the job.

No other drill is really recommended for this type of job other than maybe a Milwaukee hole hog, which is intended to drill through wood and is used by electricians mainly.

I see a lot of people who think a hammer drill can handle this task because it is a heavier duty type of drill, but it is prone to the same problems and will eventually overheat, start smoking and may even die in the process.

Features That Can Make The Difference:

Not all drills have the same features, most of them function the same way and have very similar gear ratios and are able to take the abuse that other drills can't but feature wise they can be quite different.

Variable Speed: Some drills have variable speeds that you can use for mixing up different materials, for instance if you were going to mix up a pox he then you would want a much lower mixing speed than if you are mixing up concrete. Having an variable speed trigger or dial can make all the difference in the world and make it really convenient to mix up specialty materials like that.

Dual Paddles: Some of these mixing drills actually have two paddles instead of just one and really makes the job go a lot faster (mixing material) and it is a little bit easier on the user because it does not have as much torque as one paddle would.

Trigger Placement: You may not think that something like where the triggers located would be that significant, but it really is and to make a huge difference.

Most of the time the triggers are placed in the standard position, like they would be on a standard drill, but some models have them positioned under the handle, more like the setup you would find on a chainsaw and it is much more comfortable for the user and has a much more natural feel to it.

Are These Only Used For Mixing Material?

These are primarily made for mixing different materials like stucco, mortar, thinset, epoxy and concrete, but because of the way they are geared so low and have a lower RPM than traditional drills they can also be used for drilling large diameter holes very easily.

These drills will tackle some of the toughest projects where a standard drill would fail or overheat due to the high demand of the large drill bit or the toughness of a material. This will be your go-to tool for those larger holes as well.

What Materials Can I Mix With One Of These Drills?

These are great for mixing up so many different kinds of material and are mainly used for construction type materials like stucco, mortar, concrete, thinset, mortar and other materials that are typically used during the construction process.

Some people use these for mixing up different materials such as bulk cake frosting or epoxy resins because they operate at a very low speed and have more than enough torque to span some of the toughest, thickest materials you can think of.