The wire for a one coat application is a bit more lightweight than the wire found in a three coat system but the installation is very similar. You can see my three coat wire install tutorial here.

Tools Needed:

- Metal cutting snips

- Hammer

- Roofing nails (for initial hanging of wire)

- Staple gun (that will shoot large crown staples)

- Staples for staple gun (15/16″ crown and 2 1/2″ long)

Installing The First Row of Wire:

The first row of wire is the most important and should be over the foam and tucked into the weep’s lip and should run right along the weep screed’s bottom edge. Then it’s a matter of tightening the wire and stapling it and the foam off.

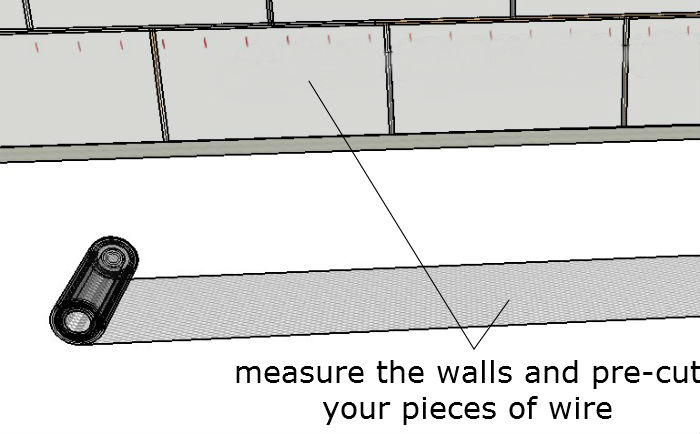

Step 1:

Precut the wire ahead of time by measuring the walls and cutting the wire to that specific measurement. This saves a ton of time and can really make the job easier.

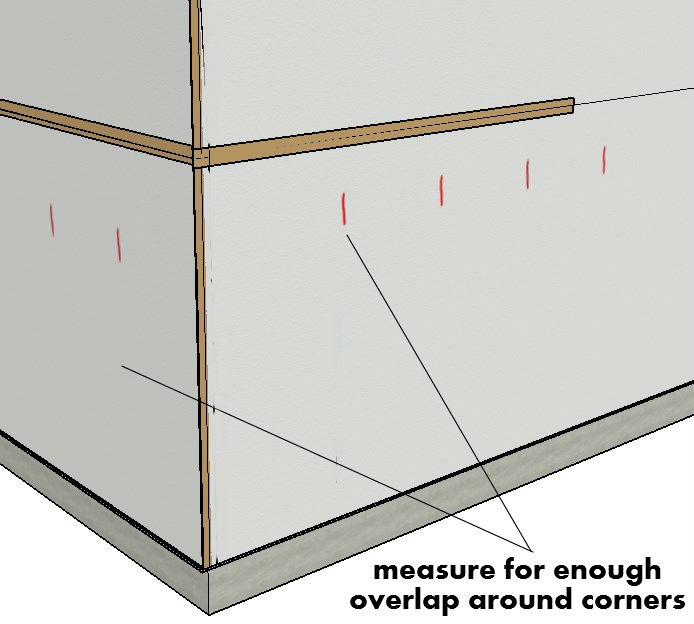

When you’re measuring, make sure you calculate enough wire to wrap around the corner and end on a stud, so you have something solid to fasten the wire to.

You can either wire over smaller windows, doors, etc. and cut them out later or you can cut the pieces to the specific dimensions, either way works.

Step 2:

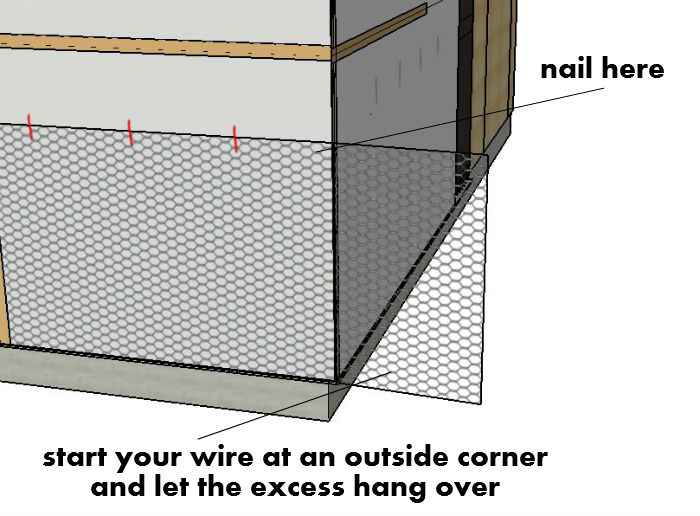

Hold your section of pre-cut wire up to the wall and hang over the necessary amount to wrap the corner and reach the stud on the other wall. Make sure your wire is resting on the bottom flange of the weep screed and is straight.

We are going to put a nail in the top corner of the wire at the corner to hold it in place while we work the rest down the wall.

Step 3:

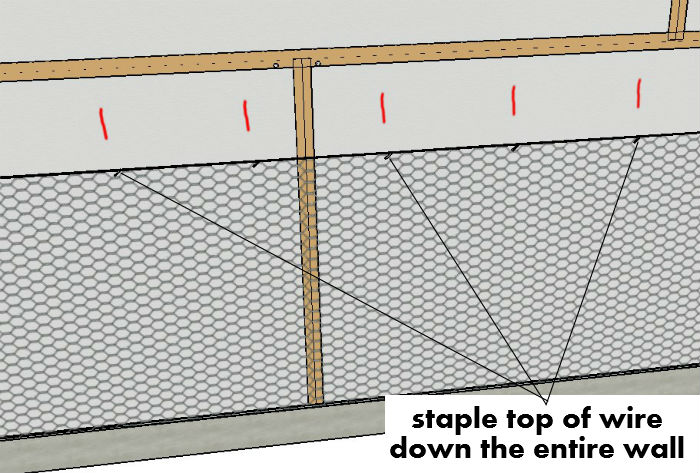

Keep the bottom edge of the wire straight with the weep screed and staple the top of the wire along the entire length of the wall, nailing on the stud marks. Keeping the bottom straight is KEY here.

Pull the wire as you go, using just moderate to light force to help lay the wire flat against the foam. Don’t pull the wire too tight, just enough to remove any sag in the wire.

Step 4:

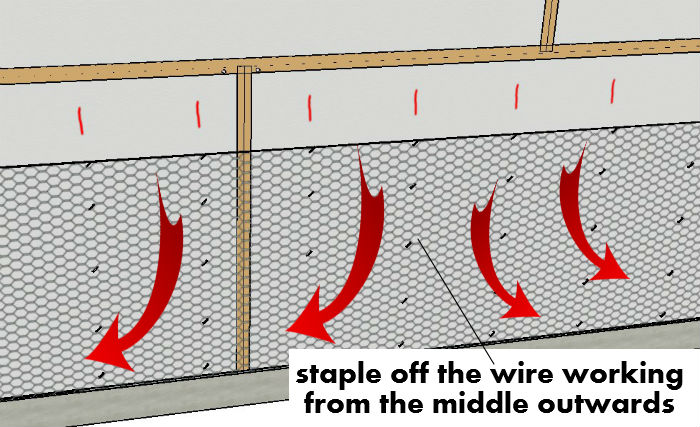

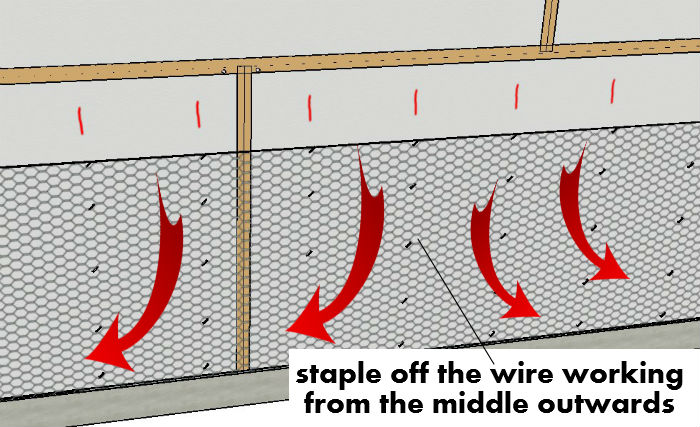

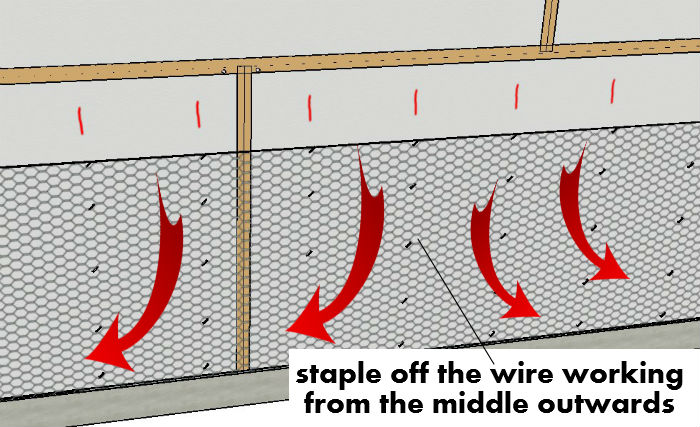

Now we are going to work the rest of the wire and staple it off as we go. Start in the center of your wall and make sure the wire is flat against the foam and touching the bottom edge of the weep screed.

Staple off the center stud every 12″ or so. Then you will want to work outwards, from the top dow repeating the process for both sides.

This will eliminate all the slack in the wire and provide a flat, straight base to apply the base coat material.

Installing The Remaining Runs:

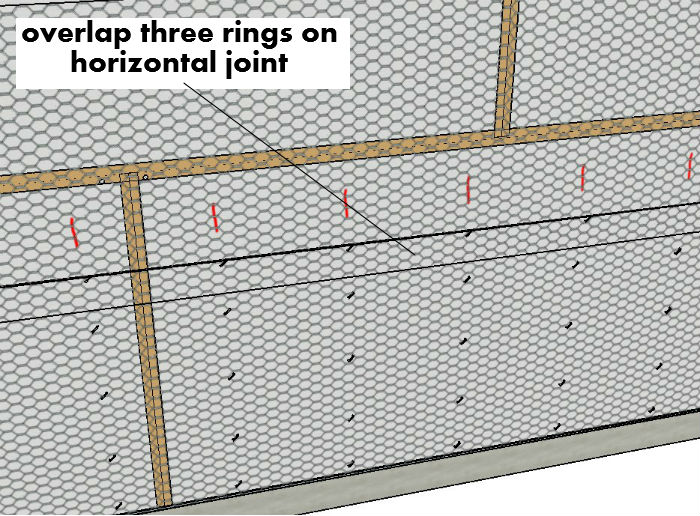

We are going to repeat the process for the remaining runs of one the coat wire and the only new thing that will get introduced is the overlap, along both the vertical and horizontal joints.

Step 1:

Installing the additional rows of wire are the exact same process but you’ll want to have a three ring overlap (about 4 1/2″) along the bottom of the new piece.

Vertical overlaps should be roughly 6″ but will be a bit more in this example to ease installation and not make the process too confusing.

Step 2:

Stapling the rest of the wire to the foam is the same process. Start in the middle, staple that stud off and make your way outwards, working from the top down.

Outside Corners:

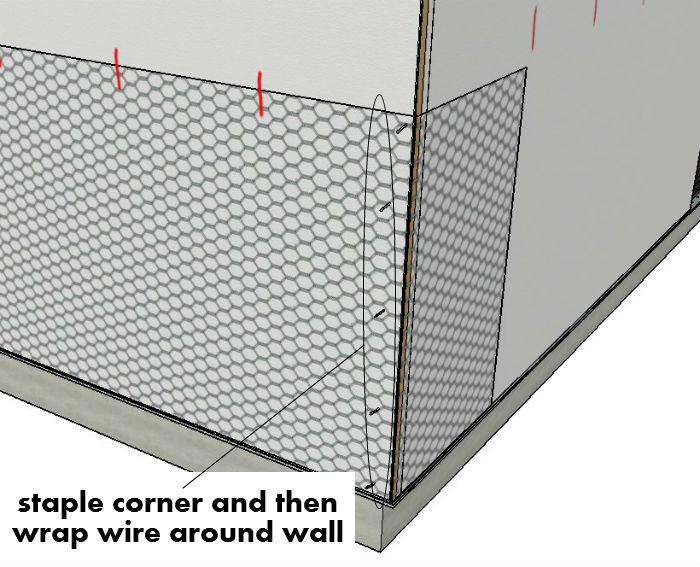

In this example, we are going to be wrapping the outside corner and attaching it to the nearest stud. Then we will be starting a new run of wire that overlaps that, making a nice and neat transition.

Step 1:

Stapling the wire in the corner before wrapping it will prevent bubbles from forming in the wire and will make wrapping the corners easier.

Staple the corner off like the picture shows, then creasing the wire using your hand to form a nice tight 90 degree angle.

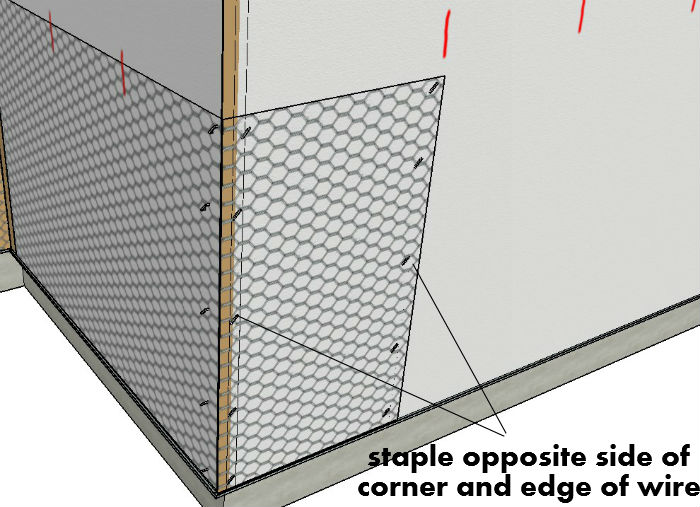

Step 2:

After you have made a nice crease in the wire, wrap it around the corner and staple the opposite side of the corner. After that is done, you can then staple the remaining edge off, making sure that your staples are penetrating the studs and not missing.

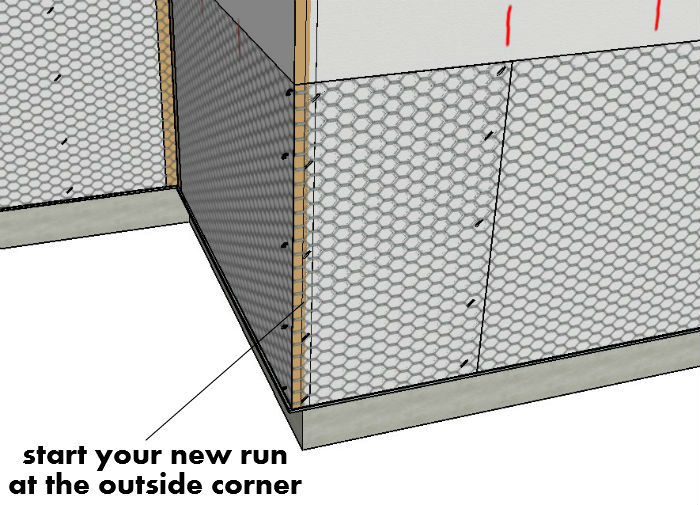

Step 3:

Start your new run of wire on the new wall on the outside corner and keep the process going.

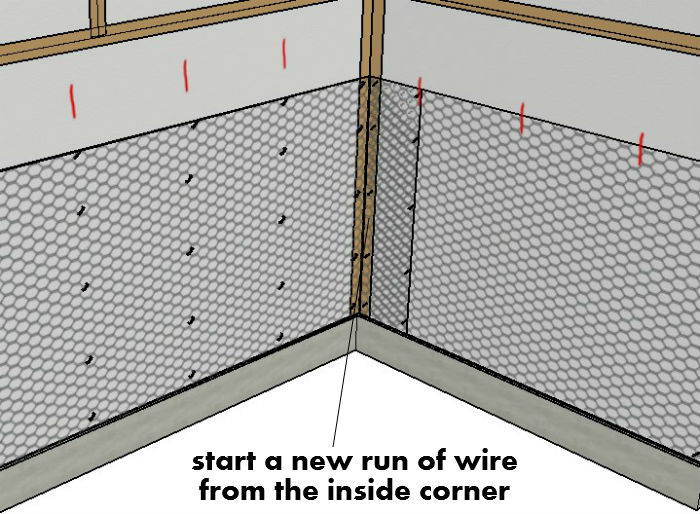

Inside Corners:

Inside corners are really no different than outside ones, you simply bend the wire the opposite way and fasten the wire systematically, in the same way.

Step 1:

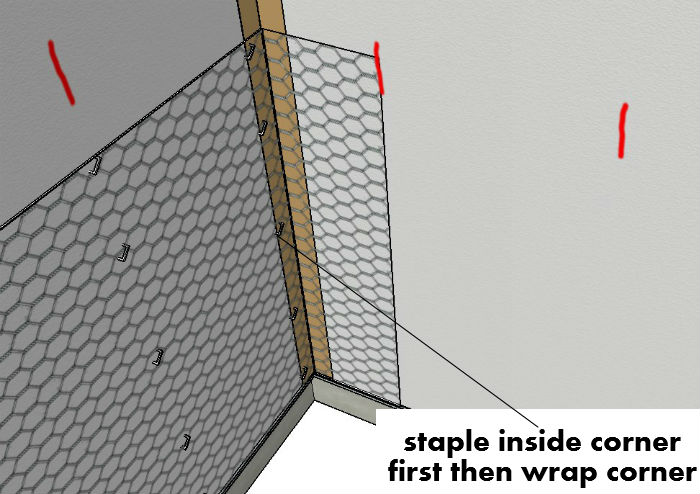

After you have your precut lengths ready to go, lay the wire along the wall, making sure your bottom edge is where it needs to be (either straight with weep or overlapping other piece of wire) and staple the one side of the inside corner, as illustrated.

Step 2:

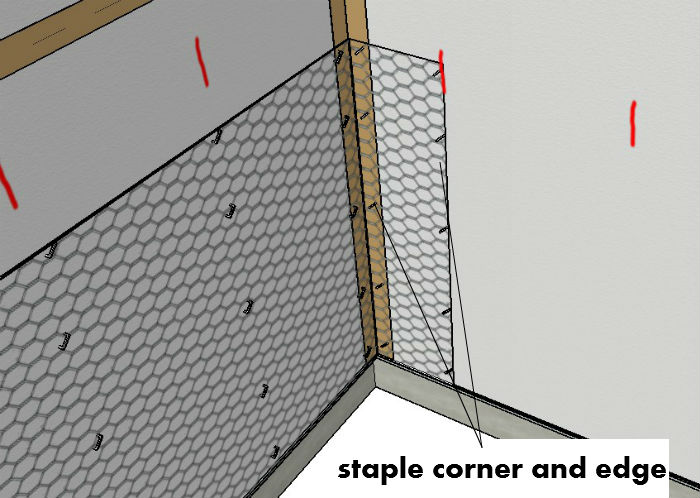

After the first corner is stapled, bend the wire to make a crease for the inside corner (bend it back onto itself) and then hold it so the wire fits nicely in the corner.

Staple off the inside corner first then finish stapling the edge off, making sure that you are nailing into a stud.

Step 3:

The last step is to continue your one coat stucco wire along the adjacent wall, starting from the inside corner and overlapping the existing wire.