There are a multitude of tools that are used in the stucco process. They range from simple hand tools like metal cutters and a hatchet to engine-driven equipment such as a mixer.

These tools make modern stucco what it is today and it is only going to get more advanced in the future.

Stucco Lathing Tools...

Lath is the first step in the stucco process and is the first tools you will need to break out and use, so I thought it would be fitting to start out the list with these first.

Tool Bags:

Bags will come in very handy when taking on your own projects, not just stucco related work but all kinds of things.

They can organize your tools and keep them close by, which will help you out more than you realize!

A Hammer:

A hammer will also need to be used because you will need it to fasten different lath components to the wall.

It is just more convenient to use a hammer and it is a tool that a lot of people can use fairly easily.

A Tape Measure:

A tape measure is one of those essential items that is needed for just about any project nowadays, including stucco lath.

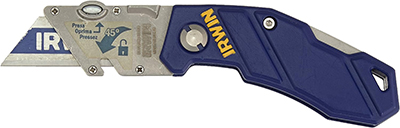

Utility Knives:

When it comes to cutting the paper, a utility knife is the best tool for the job and most people are familiar with these, but I would recommend going with one where you can change the blade out quickly, as the paper tends to wear the blades out pretty quickly.

If you are going to be cutting foam for a one coat installation, then you will need an additional knife that has an extended blade. This will make cutting through the foam much easier.

A Stapler for Attaching the Paper:

The stapler (also known as a hammer tackers) used for attaching the paper to the walls is designed to make the job easy and you only need one hand to be able to use it effectively. This particular stapler is one of my favorites and it uses smaller staples, which is all you need.

Tin Snips & Cutters

These tin snips are used in the lath process and are used to modify all the metal components that are found in stucco like the wire, corner aid, weep screed, etc. There are different sizes of metal scissors and a range of styles for specialty cuts.

The picture shows a pair of smaller tin snips that are usually used by most stucco lathers and are usually used most of the time.

These are used for cutting weep screed, plaster stop, corner aid and just about everything else that consists of metal during the lathing process.

They can come in right turn, left turn and center cut types, but a center cutting model works the best. The cutting part of the tool can also be longer than what is shown here too, making the more useful for long rips.

They also have larger cutters that some people prefer to have in addition to the smaller type of snips we looked at, but these aren't essential.

These will usually cut a little bit faster than the smaller ones because they can cut two to three pieces of wire at a time.

These are a lot more brutal on the forearm muscles too and are typically less accurate too, so keep that in mind if you plan on getting a pair for yourself.

Staple Guns for Stapling Off the Wire...

Staple Guns are an essential part of the lathing process and can speed up the time that it takes to secure the wire to the wall.

It requires a compressor and a hose to be attached to it and of course...staples.

The stapler will typically use either a 1" crown staple or a 15/16" crown staple, depending on the model.

Tools for Mixing...

You will also need the proper tools for mixing up base coats and finish coats and there are two main choices that are typically used for this.

They can be as simple as a drill with a mixing paddle attached, or a larger tow-behind, engine powered type. The tow-behind mixer is for larger areas and the drill is for smaller patches, acrylic finishes, etc.

Paddle Type Mixer/Mortar Mixer: These are the "industry standard" and are large mixers that have to be towed around by a truck.

They come in different sizes and can have either a gas or electric engine that powers them. The paddles turn inside the barrel and mix the cement, sand and water pretty thoroughly.

Barrel Type Mixer: These mixers are different from a mortar mixer because the barrel turns the material and folds it until it is thoroughly mixed. These can range in size, from larger models that have to be towed by a vehicle, to smaller ones that you can throw into the back of a truck. They come in handy for concrete or mixing other materials like garden soils and are reasonably priced, as well, making it an option for a lot of people out there.

Small Cement Mixer

Large Cement Mixer

Mixing Drill And Paddle: Mixing drills are very convenient tools to have and if you are a stucco contractor, it is mandatory!

These are the "swiss army knife" in the stucco trade and can be used for so many different things in plastering. There are many different models and types to choose from, but most work the same way and can mix just about anything, using the right technique and paddle attachment.

Tools For Applying Base Coats:

The next step in the process is to apply the base coats and you will really need these items to do that, as there really is no substitution for these. These will allow you to apply the base coat materials to the walls, using pressure and will guarantee a great result.

Scoops:

Scoops are used to transfer the cement that is inside a bucket or wheelbarrow to a plasterer's hawk. There are so many different shapes and sizes that these can come in and each one is a little different.

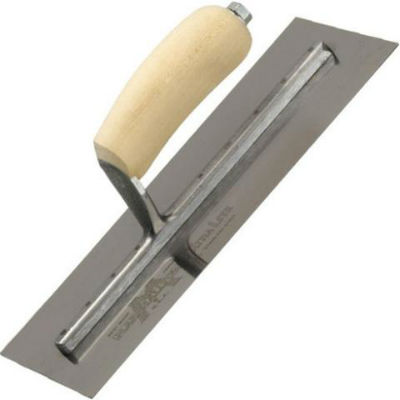

Hawk And Trowel (Applying Material):

These are the two most used tools throughout the trade... hands down. These are what a plasterer uses to apply both the base coat and finish coats to the wall.

The "hawk" is a square metallic type of surface that has a handle on it for the user to grab a hold of. It is made out of either magnesium or aluminum and is very light-weight.

The hock is made to hold smaller amounts of material on it and provides an easy way to transfer the material to your trowel and most of them are reasonably priced.

The trowel is an essential item you will need and you can find many different sizes and variations that will range in price, but I have seen decent ones for around $20-$30.

You can use a rectangular trowel or a pool trowel with rounded edges, it doesn't really matter. These also come in different finishes, but the cheaper steel models will be just fine for applying base coats.

Margin And Pointing Trowels (Applying Material):

These are handy tools that allow you to get into those tight spaces around the house that your larger trowel would not be able to fit.

The margin trowel is a small rectangular shaped tool that is great for narrow spots that are smaller than the width of your trowel and for scraping. The pointing trowel is used where a regular or even a margin trowel cannot reach, primarily gable peaks and triangular shaped areas.

Margin Trowel

Pointing Trowel

The Go Devil (Applying Material):

This particular tool has many names: a go devil, a boogie board, a cheater board and so on. This is a great tool that is used for scratch or brown coats. These are a little harder to find but are still available.

It holds 2-3 times the amount of cement that a hawk and trowel does and greatly speeds up the process of applying the material to the wall and are usually easier to use.

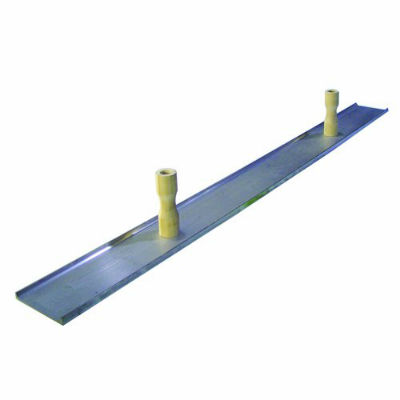

A Darby ( Brown Coat Only):

A darby is used specifically on the brown coat, but is an essential tool that you need to have to get the brown coat done properly. They are reasonably priced too.

It is basically a long trowel tool that has two handles on it. It is used to make sure that the material is spread evenly on the brown coat of stucco and removes any low or high spots in the wall.

The edges can be serrated or smooth and can even have one side smooth and the other serrated, so they are a personal preference tool for many plasterers. These take some time to master.

A Feather Edge ( Brown Coat Only):

A feather edge is a lot like a darby and can help to level out the brown coat by gliding it across the wall and placing pressure in certain areas to move the material from high spots to low spots.

It can also be used for scraping the brown coat prior to floating it.

These can come in many different lengths though, some being 8' in length or longer, which would require two people to use effectively.

A Scratcher Or Scarifier (Scratch Coat Only):

A scratcher or scarifier is a tool that is used to make small indentions in the material that produces a rough finish that the brown coat can stick to. Some plasterers use tape on them to provide a cleaner, more controlled look in the end.

These are only used for a three coat stucco process, one coat stucco systems do not require a scratch coat or scratcher tool.

Stucco Floats (Cleaning & Finishing)

Floats are basically a sponge that has a handle mounted on it and they are used in all of the process that require cement to be applied.

They are available in different varieties of coarseness to allow for more customizable options.

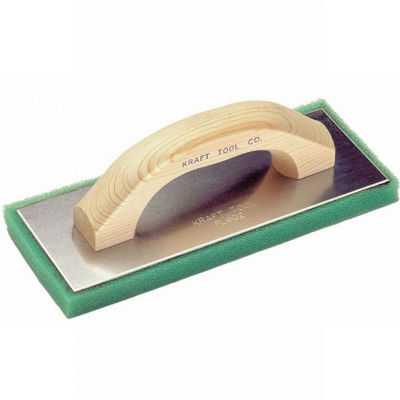

Green Float: Green Floats are some of the most common floats used throughout the stucco process, in fact they are used for nearly every phase except for lath!

They have a sort sponge like material attached to them which is a green color (hence the name) and are used to clean tools, feather in edges around stucco patch areas, as a finishing tool for some finishes/textures and as a multipurpose cleaning tool.

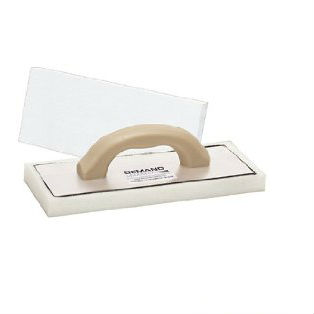

Other Soft Floats: There are other floats available that serve the same purpose and that a green float does, but have different levels of coarseness in reference to the sponge part of the tool.

A green float provides a medium finish texture when used, or something close to that.

They have coarse, medium, fine and even super fine sponges. These will create a little different textures because of this.

Red Float: Red floats are not as useful as a green float, but they do serve their purpose and are helpful for a couple of different things.

I like using these for patches because they allow me to move the mud into the existing stucco, along the edges of the patch, easier than a trowel would.

A standard steel trowel is rigid and won't flex, so getting mud to stick in these areas requires a special tool, a red float!

I know a lot of plasterers that like to use these to spread the finish coat, it is easier on the joints but will apply the material thicker than you would using a trowel.

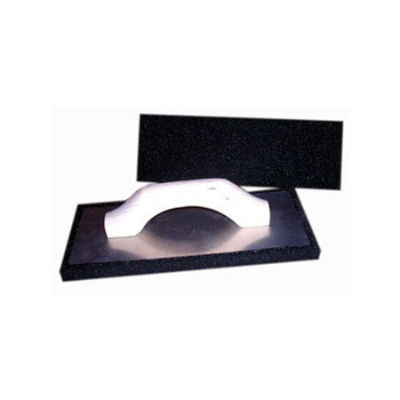

Hard Rubber Float: These only have one main purpose and that is to float the brown coat of the stucco process.

It is used in circular motions to compact the cement and sand mixture, helping to minimize cracking and increasing the overall surface strength of the base coat.

That is all they are really used for but they are specifically made for this and no other tool can substitute and be as effective.

Tools For Finishing:

There are many different tools that are used for finishing and some of them have already been mentioned like the hawk and trowel and the green float, but there are other tools that are used specifically for finishing stucco.

Plastic Floats For A Special Kind Of Finish:

Plastic floats are used for specific types of finishes and for exterior stucco the two most common textures are a trowel float finish or a worm type finish. You basically use circular motions with the trowel to get the desired texture.

These are sometimes used in interior plastering as well but not as often as a stainless steel trowel. Interior plaster is oftentimes white in color so a rusty trowel would discolor the finish.

Dash Brush For A Dash Finish:

These are used on the finish coat for traditional stucco finishes and are ideal for small to medium areas. It holds the cement on the bristles and is then flicked on the wall to create a series of splatters, which are knocked down by a trowel a little later.

This creates a unique texture that is commonly known as a dash or knockdown texture.

I do plan on constantly adding to this list over time and I'm sure it will end up being a huge list of some of the best stucco tools out there, GUARANTEED!

Let me know if you would like me to add a tool to the list (via the comments) and I will happily do so!